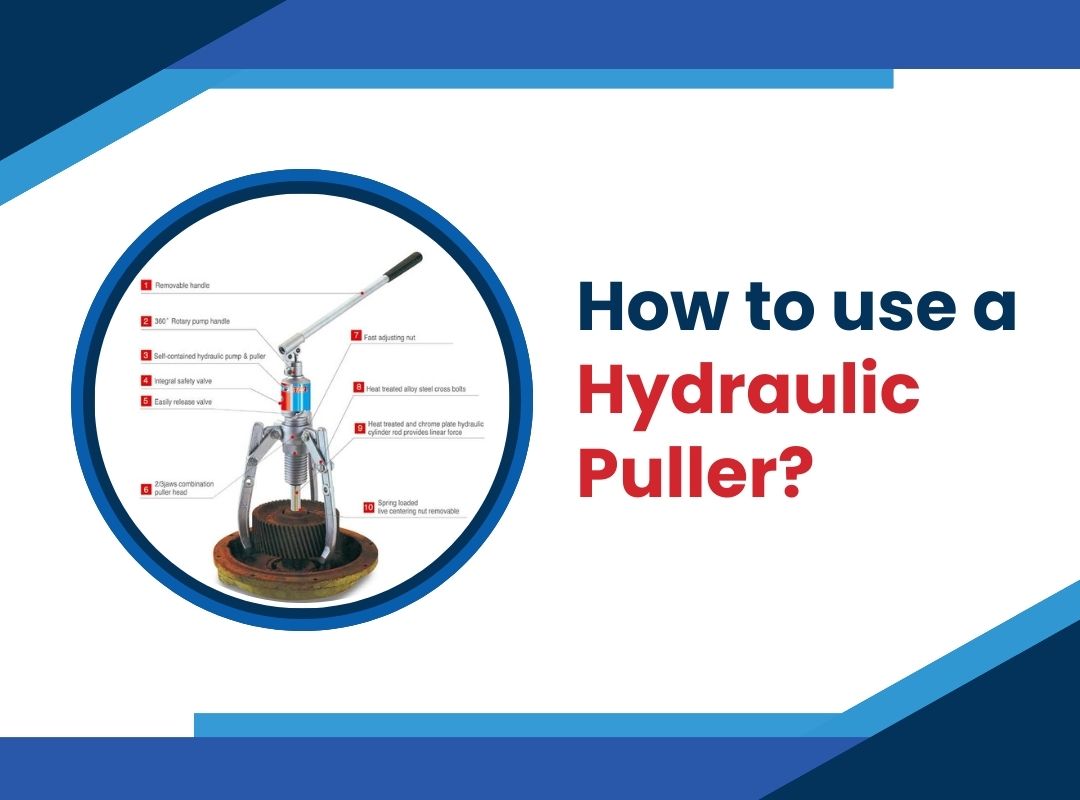

Hydraulic pullers are powerful tools used to remove parts or separate assemblies that are stuck together due to rust, corrosion, or over-tightening. With the right techniques, hydraulic pullers can safely apply concentrated pulling force and remove components that cannot be disassembled by other methods. Here is a step-by-step overview of how to properly use a hydraulic puller:

Selecting the Right Hydraulic Puller

The first step is choosing the right type of hydraulic puller for the specific job. Key factors to consider are:

- Size of the puller – Make sure the arms open wide enough to fit around the part being pulled. Measure the diameter of the component.

- Pulling capacity – Select a puller rated for the amount of force needed to pull the parts apart. Consider factors like how tightly stuck the components are.

- Arm configuration – Choose between two-arm, three-arm, or specialized pullers depending on the pulling application.

- Interchangeable accessory heads – For versatility, select a puller with removable heads that can accommodate different pulling jobs.

Proper puller selection helps prevent failures and damage during use. Refer to the manufacturer’s guidelines for capacities, accessories, and configurations available.

Also, Read: How to Select a Hydraulic Puller Safely

Preparing the Work Area

Once the right puller is chosen, set up the workspace. Make sure the area:

- Has room to maneuver the puller safely.

- Is clear of obstructions.

- Has a sturdy base where the puller and parts can be secured.

It’s also essential to have the necessary tools close at hand. This typically includes pump attachments, hydraulic fluid, a wrench set, rags, penetrating oil, and personal protective equipment like gloves and eye protection.

Disassembling Assemblies

If attempting to separate two assembled parts, first disassemble any connecting hardware like bolts, screws or retaining rings. This allows clean separation when force is applied.

Use penetrating oils and rust breakers to loosen up stuck connections prior to pulling. Removing surrounding obstructions also allows freer movement when the parts separate.

Positioning the Puller

Proper puller positioning is critical for safe operation. Follow these guidelines:

- Center the puller arms on the component to distribute the pulling force evenly. Off-center pulling risks tool damage or part fractures.

- Align the force along the axis of the part being removed. Pulling at angles puts strain on components.

- Support the part being pulled properly with braces, vises, or blocks to prevent shifting when force is applied.

- Immobilize the base structure with clamps so it does not move during pulling.

Take time to correctly line up the puller and parts being separated. Rushed positioning leads to mistakes and unsafe work.

Operating the Hydraulic Puller

Once positioned, operate the puller safely by following these steps:

- Check that hydraulic fluid levels are adequate before use. Top off if low.

- Insert the pump handle attachment. Pump the handle steadily to generate hydraulic pressure.

- Apply force gradually in increments, not all at once. Frequently stop to reposition arms or supports as the parts separate.

- Increase force until the components smoothly release. Avoid sudden breakage by building pressure slowly.

- After parts detach, release pressure valves and retract the puller arms fully. This relieves stored pressure safely.

- Check separated components for damage. File burrs smooth and replace components like seals, bearings, or gaskets.

Proper operation prevents puller overload failures and workpiece damage. Follow the manufacturer’s instructions during use. Stop immediately if arms deform or components show cracking.

Finishing the Job

Once complete, finish up by:

- Thoroughly cleaning puller arms and accessories to remove workpiece debris and old lubricants.

- Lubricating puller components to prevent rusting.

- Inspecting the tool for damage after strenuous jobs. Replace worn or bent arms.

- Storing the hydraulic puller properly in a clean, dry space.

Proper cleanup and storage keeps the puller in good operating condition for future jobs.

Also, Read: What are the Different Types of Pullers

Safety Tips

Hydraulic pullers generate high pressures, making safety essential:

- Wear personal protective equipment and tie back long hair.

- Check for hydraulic oil leaks and fix any issues immediately.

- Carefully release stored pressure from arms before changing accessories.

- Inspect parts for cracks before and after pulling. Damaged parts can break explosively.

- Support heavy workpieces and puller properly. Use chains/braces to avoid tipping.

- Keep hands and body parts clear of the puller during operation.

With proper hydraulic puller selection, setup, operation, and safety protocols, most stubborn components can be disconnected quickly and efficiently. Paying attention to these best practices will lead to safe, effective use and prevent tool damage or workplace injuries when performing pulling jobs.